We constantly get asked "what's the difference between Stage 1 and Stage 2 Sound Deadener ?" Here's the low down on how both products work.

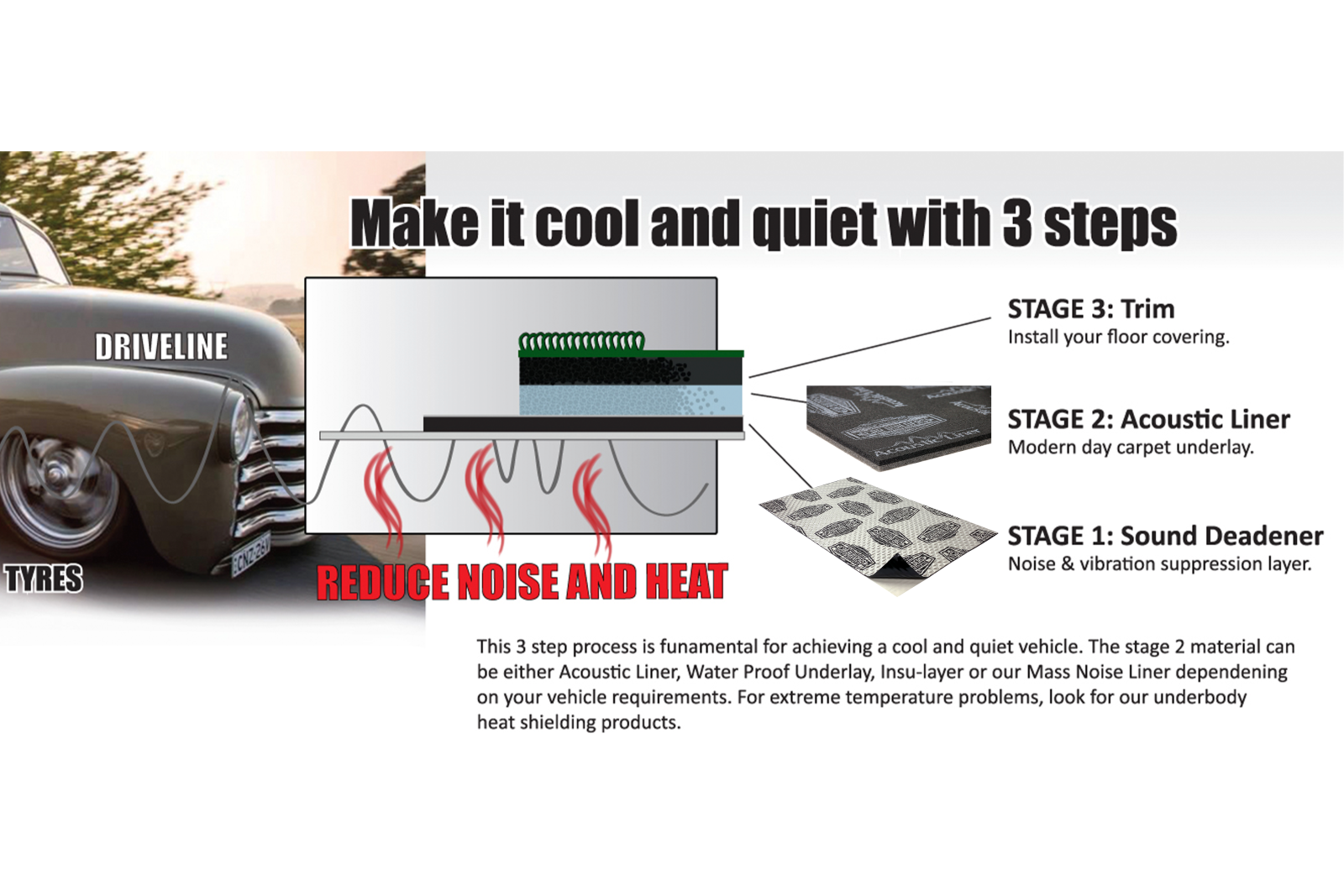

Stage 1 Sound Deadener is commonly referred to as constrained layer dampening mat, it works much like a shock absorber for sound waves. Sound waves are generated from drive line, moving mechanical parts, tyre contact with road surface and airflow over/under the vehicle. This creates airborne sounds waves which move through the vehicle structure and enter the cabin space. By applying a constrained layer dampening material to the sheet metal floor pan and firewall the sound energy is effectively absorbed and reduced, much like the spring rebound is controlled by your shock absorbers. This in effect reduces the amount of sound experienced in the vehicle. Where there is exposed single skin sheet metal you will experience noise, areas such as your firewall, trans tunnel, foot wells and particularly rear firewall in a commercial vehicle.

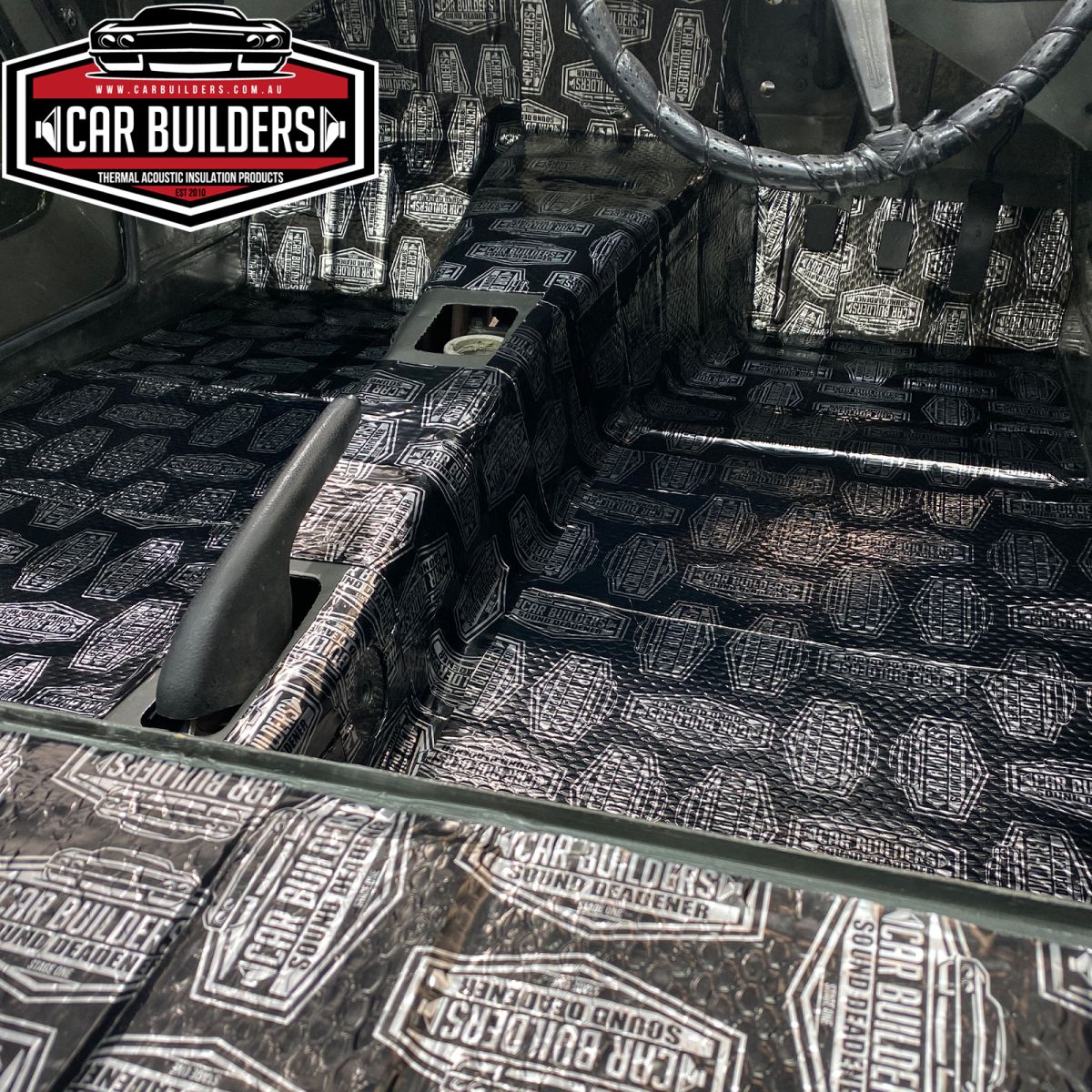

(NOTE: Stage 1 sound Deadener is avaialble in black or silver finish, both versions are the same it's simply a choice of colours.)

Stage 1 Sound Deadener is most effective in reducing low range sound frequency, however is not a one fix solution. Stage 2 “Acoustic Liner” supports stage 1 by absorbing sound energy, redirecting and muffling sound waves with its cellular structure and effectively soaking it like a sponge to water. Stage 2 Acoustic Liner is also a superior modern day carpet underlay.

When you replace your flooring in your car you need some form of underlay. This offers a perception of quality carpet and padding over all the corrugations to minimize hard edges where heels and feet can easily wear through your carpet. Underlay also offers a form of thermal insulation. Most vehicle manufactures in the 50's/60's used a form of sisal, in the 70's 80's a form of cotton jute was used and from the 90's on vehicle manufactures started to co-mould foam to carpets.

Our Acoustic Liner comprises of an absorbing layer of open cell foam, with a upper layer of closed cell foam. It uses modern day technology and the advanced benefit of the closed cell top layer foam is it offeres superior heat insulation (same material used to lag hot water pipes) It also has a smooth cast face which does not allow for water to penetrate the foam, unlike old cotton jute which start to grow mold and smell at the sight of water. The benefit is if you spill liquid ontop of the carpet its not going to soak into your underlay and down to your floorpan.

So to simplify things

- Stage 1 reduces sound through absorbing energy as a vibration dampening mat. Reduces radiant heat by acting as a heat sink.

- Stage 2 absorbs sound, reduces heat further by decoupling the heat sink effect from stage 1. Fills out carpet to create a quality feel

- Stage 3 Carpet creates a durable floor covering, makes things look pretty and feel comfortable.